Examec has a management system based on various ISO standards, e.g. ISO13485 which covers medical technology. Here are various quality-assuring working methods which are generally used at Examec and which include e.g. specific defined and risk-assessed processes (for purchasing, processing, assembly, etc.), traceability, certificate of conformity (COC) etc.

Examec has a management system based on various ISO standards, e.g. ISO13485 which covers medical technology. Here are various quality-assuring working methods which are generally used at Examec and which include e.g. specific defined and risk-assessed processes (for purchasing, processing, assembly, etc.), traceability, certificate of conformity (COC) etc.

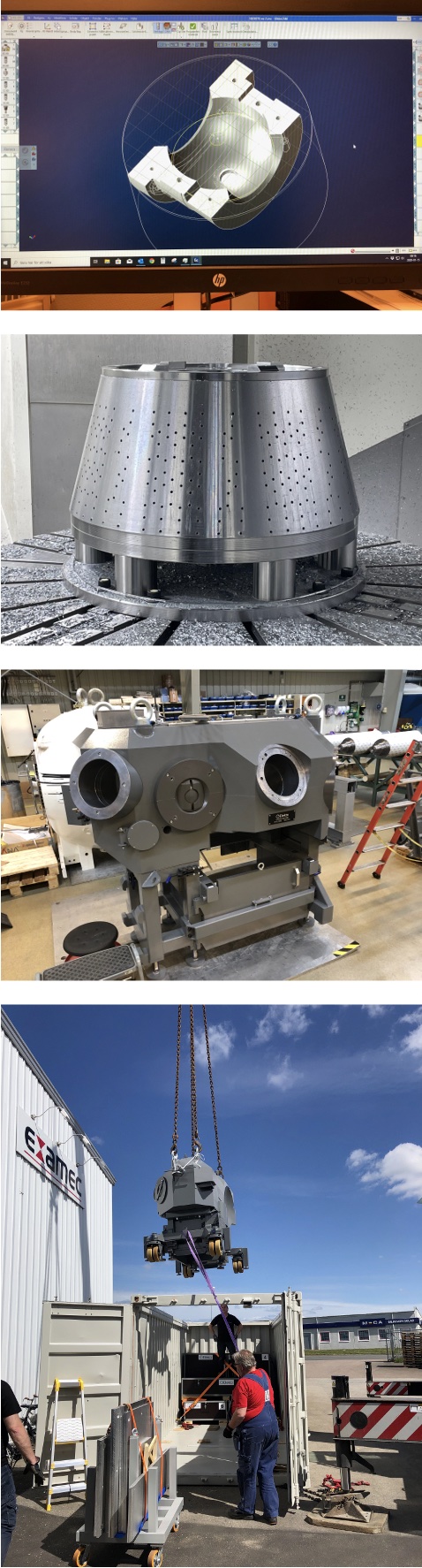

All this to ensure that every machine and every detail is completely as specified from the beginning.

All this to ensure that every machine and every detail is completely as specified from the beginning.

This is a prerequisite for customer satisfaction, delivery precision and competitiveness.

A central function for verifying that we have met the set requirements is our measuring lab. Here we have many different calibrated instruments at our disposal, from simple, manual, to very advanced. In our Mitutoyo coordinate measuring machine (with new software 2022) we can measure in the area 1000 x 800 x 800mm, there are also measuring arms, surface evenness meters, condition thickness meters, dynamometers, electronic weight meters up to 15 tons, temperature meters, pressure meters, etc.

In all manufacturing of parts, all values of the first part are measured and thereafter according to a statistical routine, or according to the customer’s wishes. All measurement protocols are examined and all work cards with the respective protocols are scanned and archived. Within medical technology, they must be archived for 21 years.

In case the customer wishes, we provide details to third parties for validation. With all these routines, we can guarantee that the part or machine, small or large, is manufactured and has the function specified by the customer.

For questions related to metrology and quality control, please contact:

Åsa Simeth

Åsa Simeth

+46 417-788 86