Machine installation

Machine installation

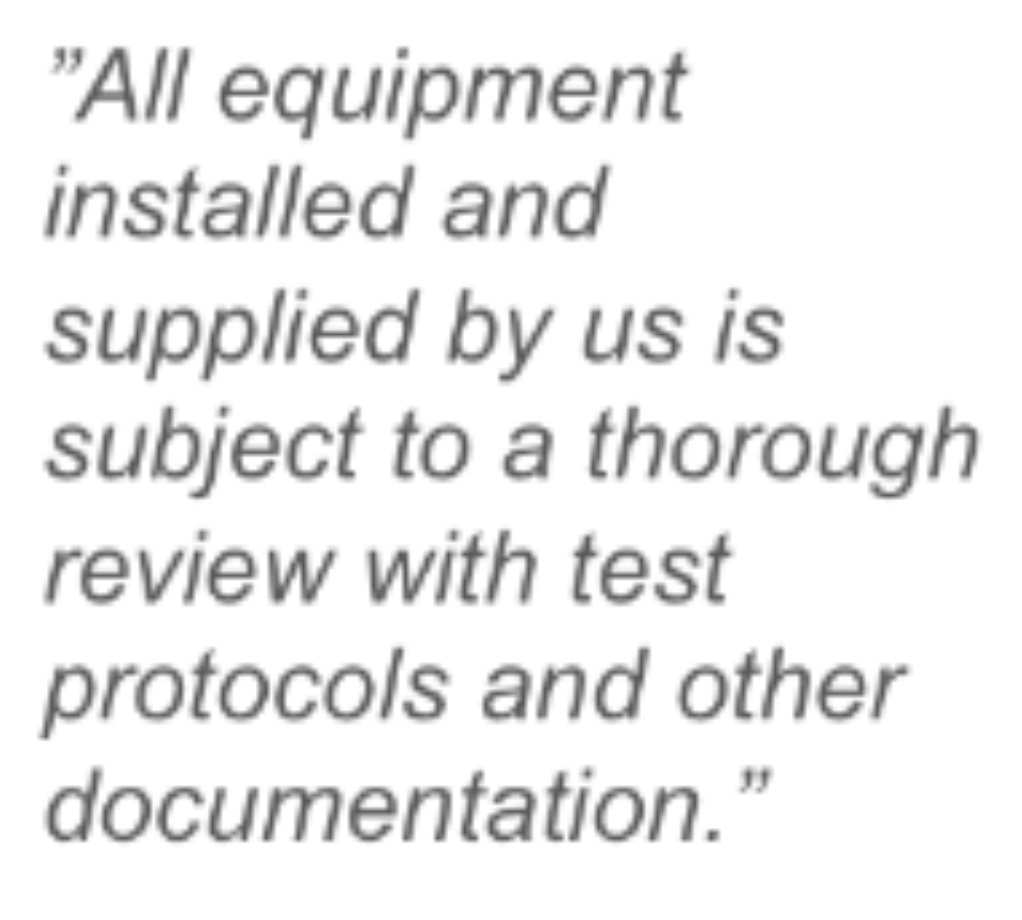

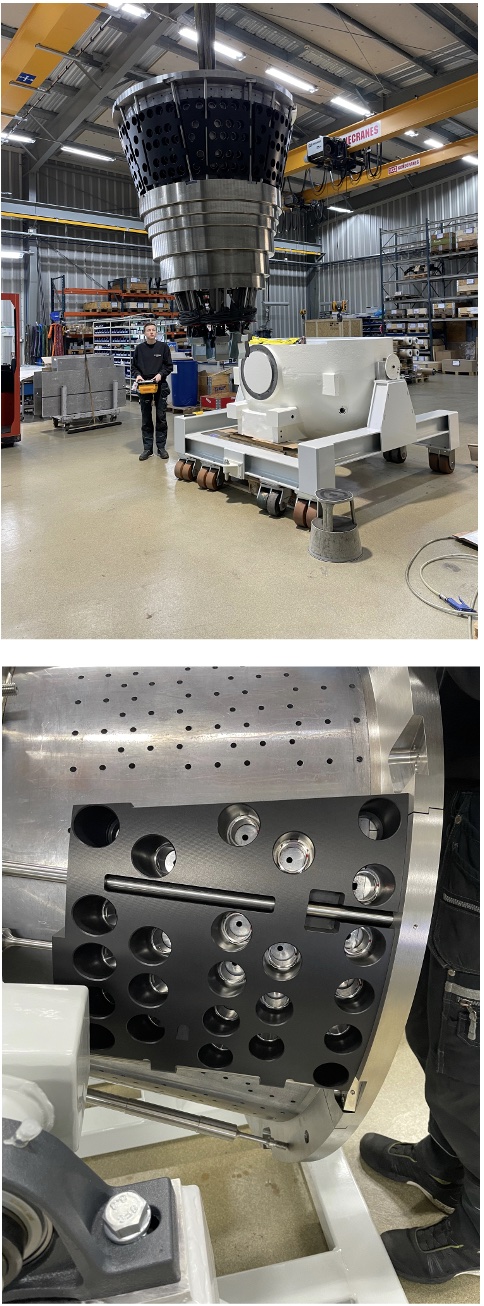

A myriad of details and components are assembled together with electrical and automation systems to make a functioning unit. By way of example, we manufacture temperature compensated creasing machines for large printing lines, complete cooling systems for operating pressure 10 bar, injection moulding units with a capacity of 9,000 shots per hour. Start-up and final testing is often done with simulators and load rigs. Skilled and motivated employees have built hundreds of machines over the years to exact specifications.

A myriad of details and components are assembled together with electrical and automation systems to make a functioning unit. By way of example, we manufacture temperature compensated creasing machines for large printing lines, complete cooling systems for operating pressure 10 bar, injection moulding units with a capacity of 9,000 shots per hour. Start-up and final testing is often done with simulators and load rigs. Skilled and motivated employees have built hundreds of machines over the years to exact specifications.

Our fitters have years of experience in installation in a range of industries. We perform installation at home, at our facilities in Tomelilla and in the field at our customers. All equipment installed and supplied by us is subject to a thorough review with test protocols and other documentation. The training of customer personnel is also conducted if requested by the customer.

Our fitters have years of experience in installation in a range of industries. We perform installation at home, at our facilities in Tomelilla and in the field at our customers. All equipment installed and supplied by us is subject to a thorough review with test protocols and other documentation. The training of customer personnel is also conducted if requested by the customer.

We also undertake assignments to build special machines for customers who need a specific solution. This may be to streamline the customer’s production line, or to start up production at the customer. Within our group of companies we have access to all the skills necessary to be an effective force.

It goes without saying that we take full responsibility for the performance of the equipment we supply.

We primarily serve customers within the medical technology, big science and packaging industries but clients from other areas are equally welcome. Our assignments consist of turnkey solutions where we construct complete machines, or sub-assemblies whereby we deliver sub-assembled machine modules.

Our customers often appreciate our precision in terms of both quality and delivery reliability. Our customers also recognise a major advantage in that we take full responsibility for the complete delivery, which means there is no doubt who to contact if problems arise.

For questions related to machine assembly, please contact:

Mikael Karlsson

Mikael Karlsson

+46 417-788 83