Advanced machinery with the highest precision

Advanced machinery with the highest precision![]()

![]()

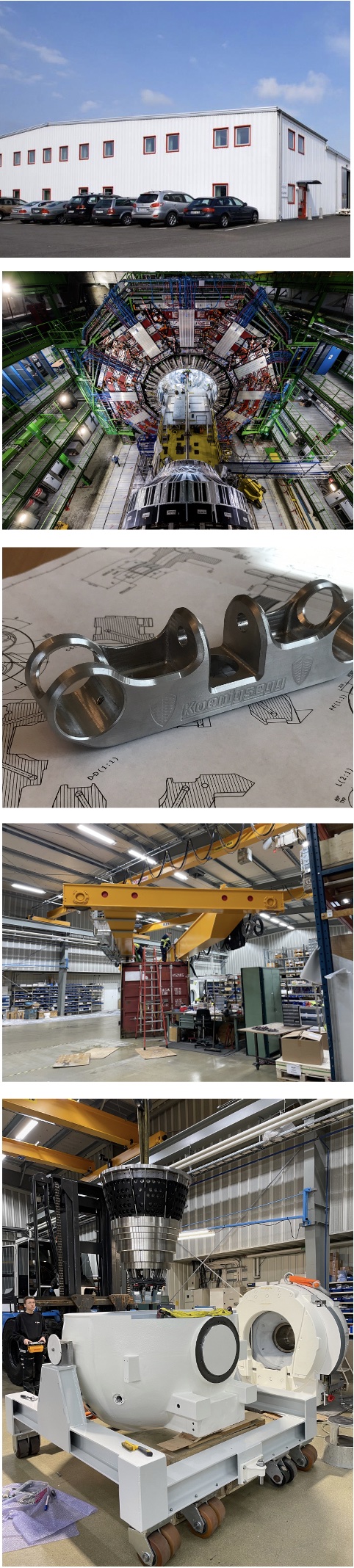

Examec specialises in high precision components and advanced machine engineering in smaller series. Our speciality is building machines with the highest requirements for reliability, where any hassle or incident would imply serious consequences. Wether concerning patient safety, loss of production, food safety or faulty scientific data.

Examec specialises in high precision components and advanced machine engineering in smaller series. Our speciality is building machines with the highest requirements for reliability, where any hassle or incident would imply serious consequences. Wether concerning patient safety, loss of production, food safety or faulty scientific data.

Our strength lies in our turnkey responsibility, complex assembly and in making components with the highest precision, particularly larger components. Our high quality and our aim for the utmost precision stems from our production management practice that follows the principles of Lean Manufacturing. In this, our metrology department plays an important role in verifying our promises.

By way of example, we build complete modules for larger

printing presses and are extremely competent in manufacturing rollers with the highest precision.

We even have our own patent for carbon fibre rolls.

We even have our own patent for carbon fibre rolls.

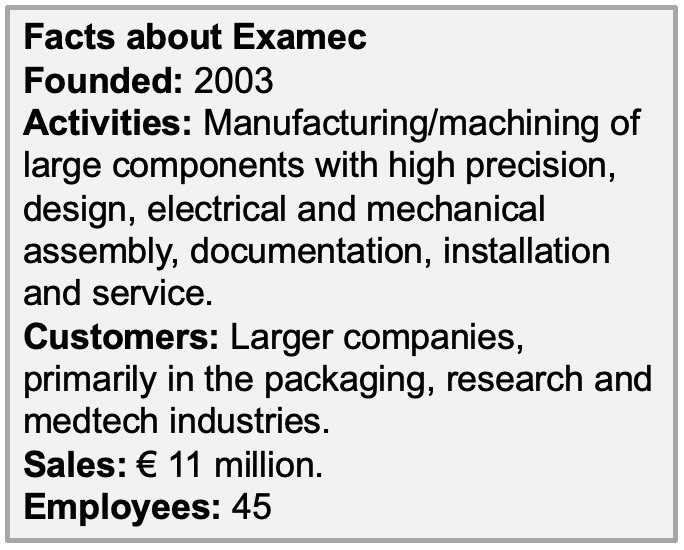

We also have a framework agreement with MaxLab IV in Lund, Sweden and we have also won procurements from European Spallation Source (ESS) for machines and rigs for scientific applications and technological development etc.

From design and project management to electrical applications, automation and final testing. We have most of it under one roof.

As a system supplier to major international companies, we often undertake turnkey

responsibility and deliver larger modules directly to our client’s flow of production.

In our company community we have a great bunch of talented craftsmen and -women who possess both highly developed skills and a high level of ambition and service. We have modern and well maintained machinery, and we design in Solid Works, Creo Elements, Auto Cad and Vector Works.

And sometimes we might even get a visit from the local baker holding a broken dough hook with a worried look on his face.

And obviously we will help him out too.

“Doing business with Examec means investing in your own future.”