Advanced machinery and full responsibility

Advanced machinery and full responsibility

Examec specialises in advanced machine engineering in smaller series. Our speciality is building machines with the highest requirements for reliability, where any problems or breakdowns would result in serious consequences. This could include loss of production, food safety or erroneous scientific data. We are accustomed to taking full responsibility which is reflected in the breadth of our organisation.

Experienced project managers and designers control the process from start to delivery. Project management is conducted using the project management model PROPS, and we conduct Failure Mode and Effect Analysis (FMEA) for more complex assignments and use a range of project tools like MS Project, Project Place etc.

Experienced project managers and designers control the process from start to delivery. Project management is conducted using the project management model PROPS, and we conduct Failure Mode and Effect Analysis (FMEA) for more complex assignments and use a range of project tools like MS Project, Project Place etc.

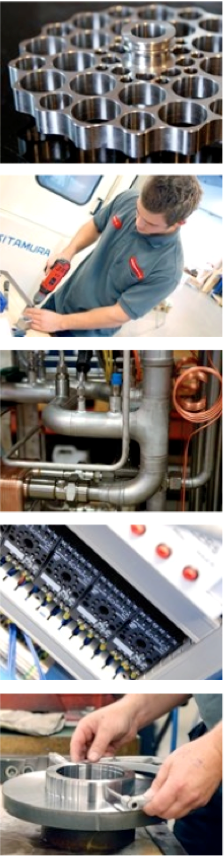

Our welding operations go back to the 1960s. The drop forging work uses gas, plasma and water cutting machines. We also accept welding and forging assignments, as well as major repair and rebuilding projects for industrial customers.

Constantly updated machinery with advanced high-quality machines and most importantly, well trained, motivated staff with many years of engineering experience ensures accurate results. We have millers with up to six axes, and machinery that combines a lathe and miller. We specialise in manufacturing larger components with high precision.

A myriad of details and components are assembled together with electrical and automation systems to make a functioning unit. By way of example, we manufacture temperature compensated creasing machines for large printing lines, complete cooling systems for operating pressure 10 bar, injection moulding units with a capacity of 9,000 shots per hour. Start-up and final testing is often done with simulators and load rigs. Skilled and motivated employees have built hundreds of machines over the years to exact specifications.

Constantly increasing demands for efficiency and versatility calls for more electronics and automation in our machines. A skilled electrical and automation department, integrated into the projects from design to final testing, is a prerequisite for absolute results.

Especially critical details are often accompanied by a measuring protocol. Hence, we have installed a Mitutoya Coordinate Measuring Machine with a work range of 1000 x 800 x 800 mm as an addition to our measuring instruments.

“Doing business with Examec means investing in your own future.”